_sm.jpg)

Ground anchors are used for transferring tensile forces from a construction to the ground. They are applied to secure stability of sheeting constructions, to ensure stability of slopes, rockfaces and cuttings, for anchoring building constructions, e.g. against upward hydrostatic pressure, etc. A ground anchor consists of three main parts: a head, a tendon and a root. The anchor tendon transfers tensile force deduced on the anchor head into the root, which is clamped by grouting in the ground. The tensile force intensity and direction of anchors influence the distribution of anchoring forces in the ground and are chosen according to the actual geotechnical conditions on the basis of knowledge about the static scheme of an anchored construction and construction composition of a bundle of anchors.

Type of anchors

From the point of view of their lifetime ground anchors are divided into temporary ones, with lifetime of up to two years, and permanent ones, with a functional time exceeding two years, usually consistent with lifetime of the anchored construction. Both types of anchors differ mainly in the way the composition of anticorrosive protection of a bundle of anchors and an anchor head is processed. Free length of the tendon is protected by PE surface, with permanent anchors in combination with oil infilling. With permanent anchors it is necessary to check their function periodically during their whole lifetime.

Anchors are produced in a central plant on an automatic assembly line for strand anchor threading and they are transported to the construction site assembled and ready for fitting into a borehole. Boreholes for ground anchors are drilled by rotary or rotary-impact method using high-performance medium-profile drilling sets. After an anchor is fitted into a borehole filled with grout, a grouting of an anchor root is carried out with cement grout, and it is repeated, if necessary, in more phases. Then an anchor head is built up from individual pieces and in a specified time period after the grouting it is possible to load the anchor. Loading is done by loading equipment according to precisely determined procedure to the values specified by the design; the anchor is put into operation by anchoring in the head. Individual phases of carrying out and testing anchors require expert and qualified workforce as well as an engineering supervision. The quality of work in the process of anchor loading is proven by tests in accordance with the Standard ČSN EN 1537 (73 1051). A method of monitoring, which records continuously deduced forces and their relevant anchor deformations, as well as stabilisation in time, was developed and is now used for a reliable sequence and control of ground anchor tests.

From the point of view of constructions and material used we divide anchors into bar and strand types. Bar anchors with a rod made of steel bars of 25, 32 or 36 mm in diameter can transfer tensile forces up to approx. 500 kN. Alternatively, it is possible to use laminated bars or bars from carboniferous fibres for production of bar anchor rods, as these prove higher resistance to corrosion compared with steel ones. Strand anchors consist of 1 to 12 strands of 15,3 or 15,7 in diameter. Their loading capacity ranges between approx. 240 to 1800 kN and is naturally influenced by a number of strands in the anchor tendon, by the way of their processing, by the fixed length of the root part, by achieved grouting pressure during the grouting of an anchor root and, last but not least, by geotechnical qualities of the ground, into which they are laid. If the mouth of a hole for an anchor is located under the groundwater level, which penetrates into the borehole due to overpressure, it is necessary to drill the borehole with a doubled drilling string sealed both in the borehole mouth and in its annulus by special preventers. If the vertical distance between the hole mouth and the groundwater level is low (up to 1-2 m), it is possible to eliminate the overpressure of water in the hole by building a casing string over the hole mouth. More and more investors put a requirement for a disposal of anchors after their functioning at a construction site is terminat ed. This requirement must be a part of the design, as it demands a special construction of an anchor bundle and placing of anchors in a way that, enables workers to access them and have enough handling space. Disposal of anchors lies in their deactivation (suppression of prestress) and removal of a head, or even a part of an anchor tendon. Both procedures are extremely dangerous and can only be realised under special safety conditions.

Different methods of using anchors

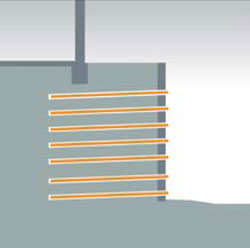

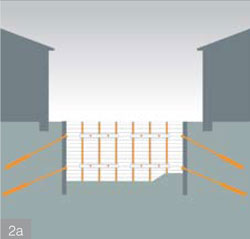

2a) anchoring of sheeting constructions of foundation pits

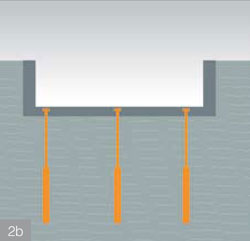

2b) anchoring of a foundation construction against upward hydrostatic pressure of ground water

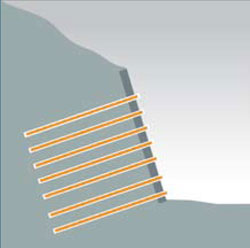

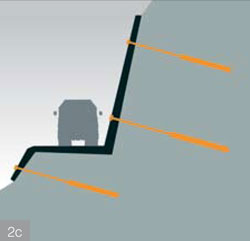

2c) static protection of slopes and trenches of engineering works

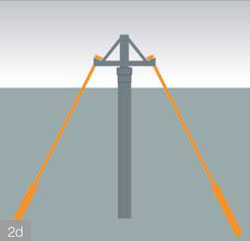

2d) using anchors for carrying out load tests

_ii_sm.jpg) NAILING OF SLOPES

NAILING OF SLOPES

Nailing of slopes represents an economically advantageous method that serves for reinforcing of soils in their natural location. The principle of this method lies in creating relatively dense network of short tensile elements in natural soils consisting of a steel reinforcement (nails) with a cement filling and lead into a covering layer of shotcrete reinforced with a steel fabric of 100-250 mm of thickness. Its head formed usually by the nail tendon flexion provides the interconnection of the nail with the covering layer. This makes a body of reinforced soil that can resist the evolving earth pressure, or possibly the surface load. The main difference between the structure described and the casing structure with ground anchors lies in the absence of vertical bearing elements, in a different way of transferring load into soil (nails transfer load at their full length) and in a generally denser mesh; the nails are not stressed. The hole diameter for nails ranges between 50 to 150 mm depending on the geological conditions. The way of dewatering these slopes or walls also represents an important part of their securing. This technology is widely used mainly as a temporary stabilisation of slopes, wall casings and excavations in cases when there is a complicated ground plan of a foundation pit, or when existing supporting walls are redeveloped. Another area of utilisation of this technology is stabilisation of slopes of trenches and embankments on line constructions in a dissected landscape.

Examples of the use of anchors for static protection of engineering constructions

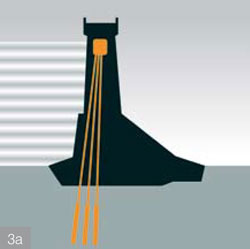

3a) hydrotechnical works

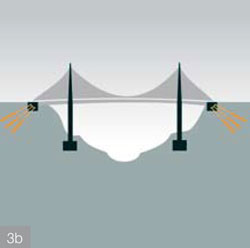

3b) bridge constructions

Nailed slopes can be inclined or vertical; the proper steel reinforcement

(nails) can be fitted horizontally or under a gentle angle